-

tel:

+86 18012590077 -

email:

laibeilizong@gmail.com -

Whatsapp:

+86 17802692659

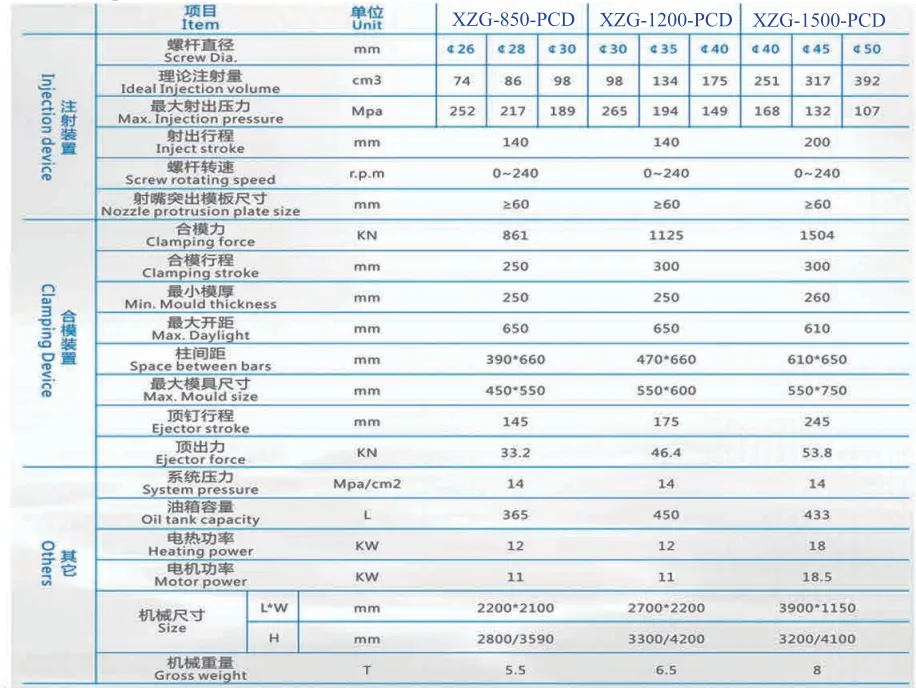

XZG-850-PCD Series

◆ Category: High precision automatic injection molding machine

◆ Introduction: The injection machine automatically extracts the raw materials mechanically, measures them at a ratio of 1:1,and accurately injects them into the mold through the screw.

◆ Advantages

Stable quality

The injection machine automatically extracts the raw materials mechanically, measures them at a ratio of 1:1. and accurately iniects them into the mold through the screw, This overcomes the problem of unstable quality of the molding press due to man-made production

Efficient

When using the iniection machine to produce, the raw materials do not need to be mixed and color matched; no manual weighing or swinging is required; all are controlled by the machine computer, automatic feeding, metering, high repeatability, double sliding plate continuous action ejection, almost no molding Time, high efficiency and stable quality, One injection machine is equivalent to the production capacity of two vulcanizers.

Intelligent

Modern rubber injection molding machines are equipped with intelligent control systems, providing full closed-loop monitoring of the production process. Operators can set and monitor key parameters such as injection pressure, speed, temperature, and time in real time via the touchscreen. The system supports storage and one-click recall of multiple mold recipes, significantly improving mold change efficiency and production transition speed.

Some high-end models also support remote monitoring and data upload, enabling remote diagnosis and management of equipment operating status, helping companies build digital factories. Functions such as automatic ejection, removal, and feeding can also be integrated with robotic arms and conveyor systems to create flexible, unmanned intelligent production lines, comprehensively improving the efficiency and stability of rubber product manufacturing.

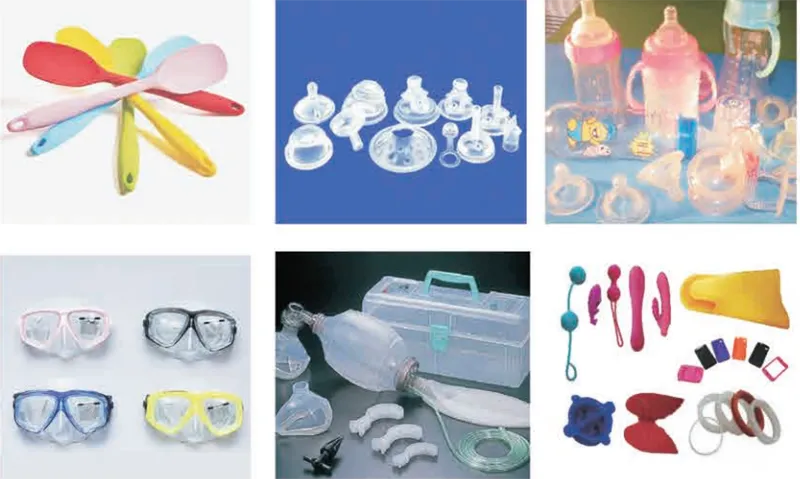

◆ Application Area

◆ FAQ

What are the advantages of a rubber injection molding machine over a traditional compression molding machine?

Rubber injection molding machines offer significant advantages over traditional compression molding equipment in terms of efficiency, product consistency, and automation. First, the injection molding machine pre-plasticizes the raw material in the syringe barrel, resulting in fast injection speeds and short molding cycles, significantly improving production efficiency. Second, the injection process is controlled by a PLC program, precisely controlling the injection volume, pressure, and time, ensuring consistent product dimensions and quality. Furthermore, this equipment is suitable for automated production, and with the integration of robotic arms, automatic mold opening, and ejection functions, it enables continuous and efficient batch processing. In contrast, traditional compression molding requires manual feeding, slow mold flow, and long curing times, and is prone to dimensional deviation and low production efficiency.

What are the raw material requirements for using a rubber injection molding machine?

Rubber injection molding machines are suitable for most thermoset rubber materials, including natural rubber, nitrile rubber, EPDM rubber, fluororubber, and silicone rubber. To achieve optimal plasticization and injection results, the raw material must possess a certain degree of plasticity, thermal stability, and flowability. In addition, the base rubber should be thoroughly mixed to achieve good uniformity to avoid problems such as uneven distribution, burning, and bubbles during the injection process. Material hardness, vulcanization system, and filler type also affect molding quality. Therefore, material selection should be tailored to the product's performance requirements and the equipment's process parameters. Certain special rubbers, such as those with high viscosity or fiber reinforcement, may require a customized screw or heating system to ensure smooth processing.

Is the rubber injection molding machine suitable for switching between multiple products?

Rubber injection molding machines are ideal for flexible switching between multiple products, especially when multiple batches, small batches, or customized production are required. These machines typically feature multiple sets of mold parameter storage, allowing operators to quickly access process recipes for different products via a touchscreen interface, shortening mold changeover time and reducing commissioning costs. Furthermore, the machine's well-designed mold mounting structure and quick-change mechanism enable rapid mold changes. Injection parameters, temperature control, and hold time can all be independently configured to meet the process requirements of different products. Some models also support multi-cavity mold production, allowing a single machine to produce multiple parts simultaneously, effectively increasing production capacity. Therefore, rubber injection molding machines are very suitable for manufacturing companies with a wide variety of products and a fast production pace.

Xiangshui Laibei Technology Co., Ltd. is a technology-based enterprise with rich experience in the design and manufacturing of rubber machinery and automation machinery, committed to providing customers with high-quality mechanical services.

Our company adheres to the principle of standardized operation, insists on the concept of quality improvement and product innovation, provides various customized products, and offers customers technical consultation, research and development, manufacturing, factory planning, and whole plant output services. Through rapid customer service processing, operator training, and comprehensive assistance before and after sales, we provide customers with the best products.