-

tel:

+86 18012590077 -

email:

laibeilizong@gmail.com -

Whatsapp:

+86 17802692659

Data Monitoring System of Chemical Plant

Data Monitoring System of Chemical Plant

Against the backdrop of Industry 4.0 and the internet economy, the integration of information technology into industry has significantly boosted the innovation and productivity of the real economy. The informatization of industrial production has also provided data support for the implementation of internet concepts. The Industrial Internet of Things is accelerating industrial transformation and upgrading, resource allocation, and innovation in production management models.

It fully adopts GDI+ graphics development technology, and supports network element tools such as Echarts charts, IE controls, Chrome controls, etc. It supports dynamic optimization and static refresh of screen pixels, and supports various screen display methods such as replacement, overlay, and pop-up.

◆ Features

Improved Production Safety

The data monitoring system monitors key parameters such as temperature, pressure, flow, and gas concentration in real time. If an anomaly occurs, such as a leak, overpressure, or equipment failure, the system immediately issues an alarm, prompting operators to address it promptly, effectively preventing accidents and ensuring the safety of both personnel and equipment.

Optimized Production Efficiency

Through real-time data collection and analysis, the system helps managers understand the operating status of each process link, identify bottlenecks, and optimize process configurations. Furthermore, this data supports predictive maintenance, reducing downtime caused by equipment failures and improving overall production efficiency and stability.

Compliance and Audit Support

The data monitoring system automatically records operational and process data to meet environmental and safety regulations (such as EPA, OSHA, and ISO). Historical data and reports facilitate internal audits and government inspections, enhancing corporate transparency and credibility.

Reduced Operating Costs

The data monitoring system significantly reduces overall operating costs by reducing manual operations, energy consumption, material waste, and losses caused by equipment failures. Optimized maintenance strategies also reduce unnecessary manual maintenance costs.

Enable remote management and intelligent decision-making

Leveraging the Industrial Internet of Things (IIoT) and cloud platforms, systems can achieve remote data access and control. Combined with big data analytics and artificial intelligence technologies, enterprises can conduct predictive analysis, risk assessment, and intelligent decision-making, improving management capabilities and market responsiveness.

◆ FAQ

What is the role of a data monitoring system in a chemical plant?

A data monitoring system in a chemical plant continuously collects and analyzes real-time data from sensors, instruments, and control systems throughout the facility. It monitors variables such as temperature, pressure, flow rates, chemical concentrations, and equipment status. This system ensures operational safety, improves process efficiency, and enables early detection of abnormalities or equipment failure, helping avoid costly downtime or accidents. It’s a core part of modern plant automation and regulatory compliance.

Which technologies are commonly used in chemical plant monitoring systems?

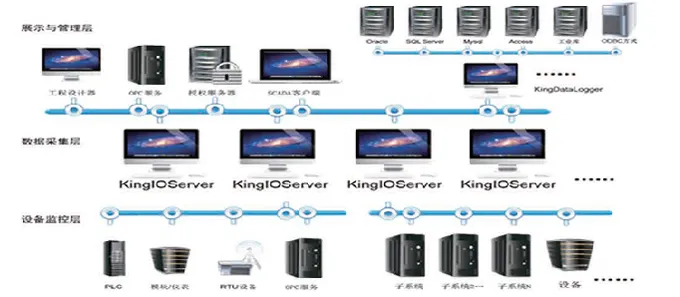

Common technologies include SCADA (Supervisory Control and Data Acquisition), DCS (Distributed Control System), PLCs (Programmable Logic Controllers), IoT-based sensors, and industrial communication protocols like Modbus or OPC UA. These technologies work together to collect, transmit, and visualize process data. Cloud platforms and AI/ML tools are increasingly integrated for advanced analytics, predictive maintenance, and remote monitoring, making the system more intelligent and proactive in decision-making.

How does a data monitoring system improve safety and compliance in chemical plants?

By providing real-time alerts and historical data logs, the monitoring system helps detect leaks, overpressure, temperature spikes, or unauthorized access. It ensures critical parameters remain within safe limits and supports immediate corrective actions. Furthermore, data logging assists in regulatory compliance with environmental and safety standards (e.g., OSHA, EPA, ISO). Reports generated from the system are also used during audits and inspections, demonstrating transparent and traceable operations.

Xiangshui Laibei Technology Co., Ltd. is a technology-based enterprise with rich experience in the design and manufacturing of rubber machinery and automation machinery, committed to providing customers with high-quality mechanical services.

Our company adheres to the principle of standardized operation, insists on the concept of quality improvement and product innovation, provides various customized products, and offers customers technical consultation, research and development, manufacturing, factory planning, and whole plant output services. Through rapid customer service processing, operator training, and comprehensive assistance before and after sales, we provide customers with the best products.