-

tel:

+86 18012590077 -

email:

laibeilizong@gmail.com -

Whatsapp:

+86 17802692659

Customized Bearing Block

Customized Bearing Block

Non-standard bearing seats are custom-developed bearing support components based on a customer's specific operating requirements, installation environment, bearing type, and operating parameters. Unlike standard bearing seats, non-standard bearing seats offer greater design flexibility and structural diversity, making them widely used in special operating conditions, non-standard machinery and equipment, automation systems, and high-precision transmission systems.

◆ Advantages

Customizable Design

Customizable designs can be tailored to meet the needs of complex or specialized working environments based on parameters such as shaft diameter, mounting method, load conditions, lubrication system, and sealing structure.

Diverse Structures

A variety of designs are available, including split, integral, adjustable, with cooling systems, and sliding seats, to accommodate diverse equipment installation requirements.

High-Quality Material Selection

Optional materials include cast iron, ductile iron, cast steel, stainless steel, and aluminum alloy, offering a balance of strength, corrosion resistance, and cost-effectiveness.

High-Precision Machining

CNC machining and precision testing ensure concentricity and parallelism of the bearing mounting surfaces, extending bearing life.

Various Seal Configurations

Labyrinth, contact, non-contact, and double seals are available, providing effective dust and water resistance and enhancing system reliability.

Lubrication System Integration Supported

Pre-requisite lubrication channels and lube nipple ports are available, making them compatible with centralized or automatic lubrication systems.

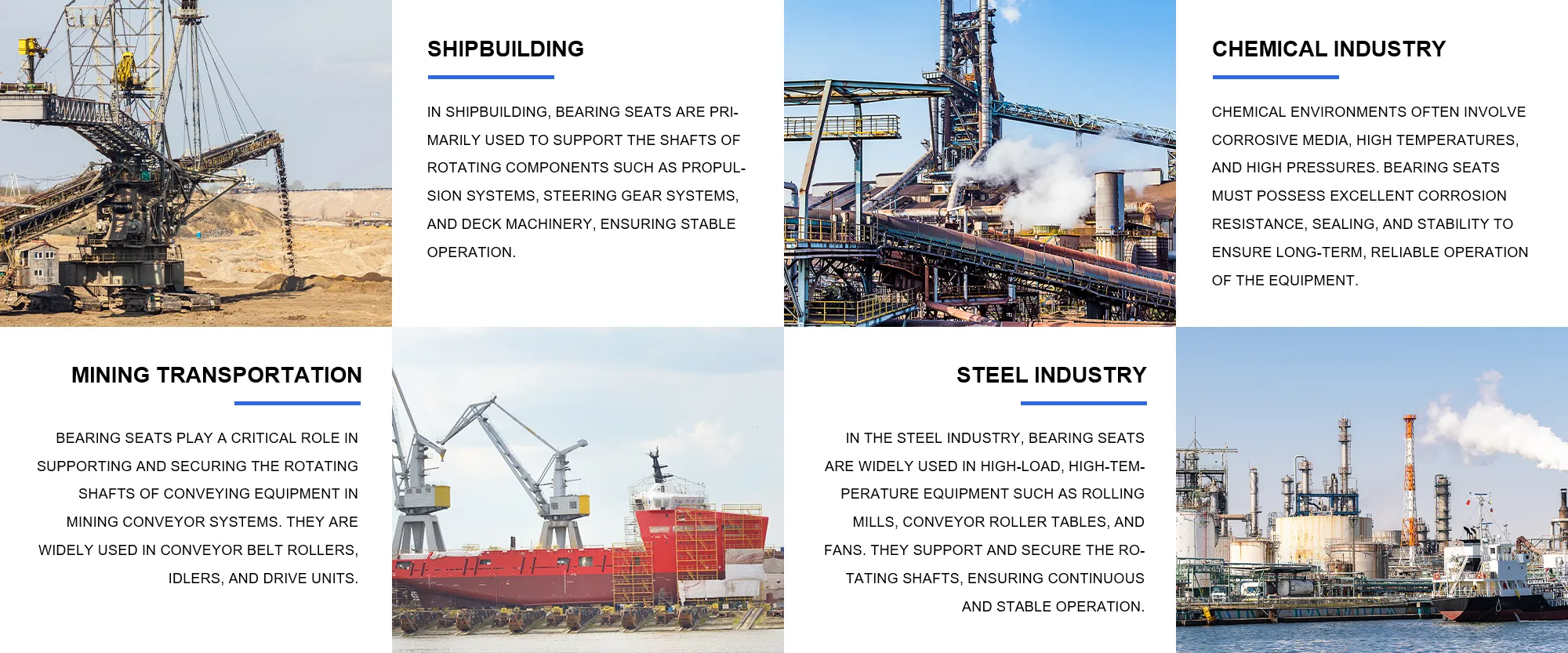

◆ Application Area

◆ FAQ

What is a Non-standard Bearing Housing and when is it needed?

A Non-standard Bearing Housing is a customized bearing support unit designed to meet specific operational, dimensional, or environmental requirements that standard housings cannot fulfill. It is typically required in situations involving special mounting constraints, unusual shaft sizes, high or low temperatures, corrosive environments, or specific industry standards. Custom housings ensure optimal performance, extended service life, and compatibility with unique machine designs.

What information is required to design a custom bearing housing?

To design a Non-standard Bearing Housing, clients should provide detailed specifications including shaft diameter, bearing type or model, load conditions (radial and axial), rotation speed, operating environment (temperature, dust, moisture), installation layout, preferred materials, and sealing or lubrication needs. 3D drawings or equipment schematics are also helpful. The more accurate the data, the more precise and reliable the final design.

How long does it take to manufacture a Non-standard Bearing Housing?

Lead time depends on the complexity of the design, material availability, and order quantity. Typically, design and prototyping take 1–3 weeks, followed by 2–4 weeks for production. Urgent orders or repeat productions may be expedited. If advanced features like integrated cooling or special coatings are required, additional time may be necessary. Clear communication during the design phase helps ensure timely delivery.

Xiangshui Laibei Technology Co., Ltd. is a technology-based enterprise with rich experience in the design and manufacturing of rubber machinery and automation machinery, committed to providing customers with high-quality mechanical services.

Our company adheres to the principle of standardized operation, insists on the concept of quality improvement and product innovation, provides various customized products, and offers customers technical consultation, research and development, manufacturing, factory planning, and whole plant output services. Through rapid customer service processing, operator training, and comprehensive assistance before and after sales, we provide customers with the best products.